Shopping for new cookware in current times is a minefield. With constant development and upgrading of the types of non-stick coatings available to us.

But how do we know which is the best? And how do we know which one will suit the task at hand better than the others?

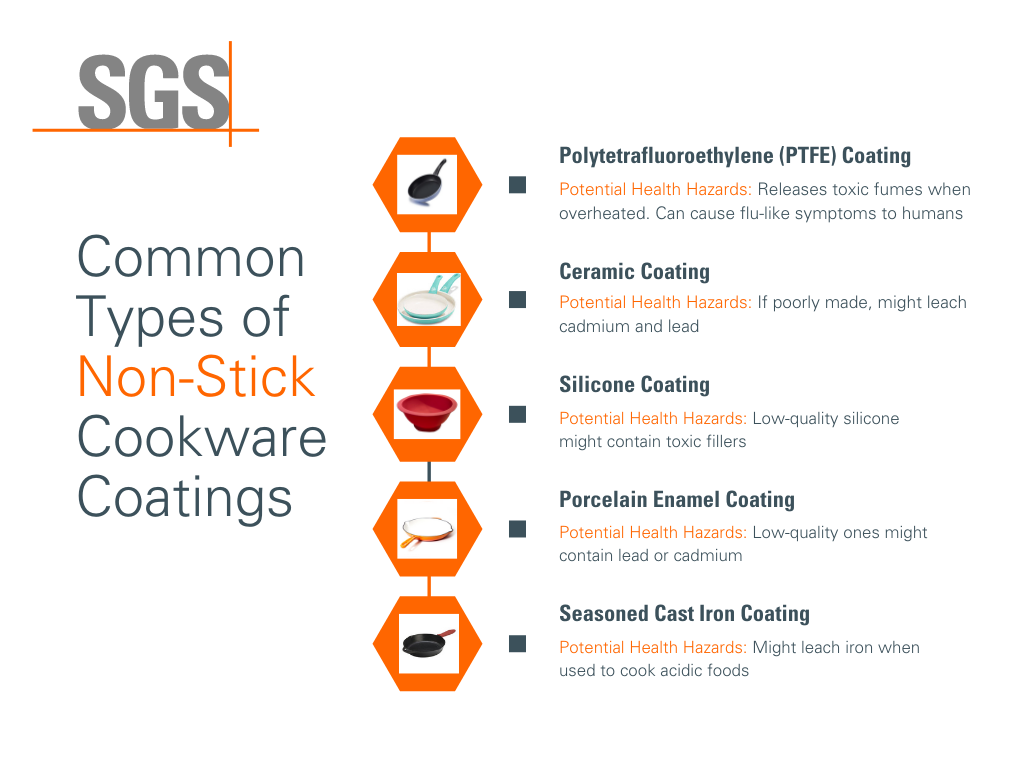

Several types of non-stick coatings that are commonly used in cookware are PTFE, silicone, ceramic, enameled & seasoned cast iron coatings. However, each material will become hazardous if used in an improper way.

In April 2022, the International Organization for Standardization (ISO) published ISO 4531:2022 for testing food contact enameled articles. It:

- Strengthens the migration limit for aluminum

- Requires the three consecutive release tests to be carried out on the same day using the same sample and a fresh test solution per test

- Stipulates test reports to include any relevant information on the uncertainty of measurement and any deviations from the procedure

In a recent market surveillance conducted by Consumer Council in Hong Kong, several types of enamel-coated cooking pots were found to release different types of heavy metals. Referencing the international standard ISO 4531 for testing:

- 1 model’s amount of aluminium, arsenic, cadmium and lithium released exceeded the standard by around 0.4 times to 16 times

- another model’s cobalt and lithium release levels exceeded the limit by around 0.6 times and 1.3 times

The test results have been referred to the Customs and Excise Department for follow-up action.

In all regions, compliance for FCM can be a complex process for economic operators. To avoid costly non-compliance, suppliers are advised to seek professional regulatory assistance for their target market.

At SGS, we carry out food contact materials testing to ensure that your products comply with the appropriate regulations.

Our aim is always to ensure food is not contaminated by the products it comes into contact with in accordance with international and regional legislation or specific quality assurance plans.