Top search:

REACH Annex

RoHS

Disinfection

GB 18401

SMETA

EN 71-1

Mask

Inquiry

Initial Production Check (IPC) is performed on site, when between 10% and 20% of your goods have been produced. We conduct AQL sampling based on ANSI/ASQ Z1.4 criteria and produce detailed inspection reports based on a defined AQL. Our quality assurance specialists can help you to identify any non-conformity so that you can implement corrective actions before consignments are completed. We will deploy our experts in even the most remote areas, providing you with significant cost savings.

SGS can also provide an Easy-to-use online portal that let you schedule and remotely manage your inspections anywhere and any time. It is a smart usage of collected data for advance reporting analysis.

Remark: SGS does not verify authenticity of any Brand/Trademark of products. Client must check if the product is genuine with the Brand/Trademark owner directly.

Initial Production Check (IPC)

![]()

Local Expertise

Our inspection team is experienced and regularly trained to ensure up to date technical knowledge and customer procedures.

![]()

Continuous Services Excellence

Full dedicated team in charge of monitoring performance and integrity.

Smart use of digital innovation to monitor inspectors activity.

Innovative spirit to ensure continuous operation even under difficult time or situation.

![]()

Global Coverage

More than 1600 inspectors operating in 80+ countries providing worldwide coverage in all main sourcing location.

1. Request A Quote

Complete the form to get an initial quote online

2. Confirm Quote

Confirm requirement, scope and schedule to finalize the quote

3. Arrange Payment

Arrange bank transfer payment and send record to us

4. Onsite Service

Conduct service based on committed schedule

5. Receive Report

Receive our audit report and certificate

It is an onsite service aiming to check the product quality, quantity, assortment, labelling/marking, and packaging condition by random sampling method at different stages, e.g. A. during manufacturing processes (i.e. During Production Check), or B. when the consignment is 100% manufactured with 80% export packed (i.e. Final Random Inspection). Defective products could be detected while client can decide to implement appropriate improvement actions afterwards.

SGS inspection service is to check the product quality on site against the reference sample/confirmed specification & requirements/Purchase Order & packing instruction. The experienced inspector will check the product quality visually, perform function test and verify the requirements as stated in the specification and Purchase Order.

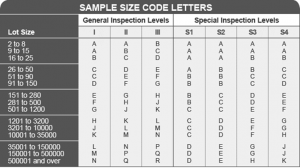

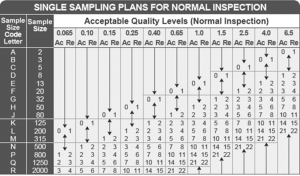

Its full name is Acceptance Quality Limit, it is the defective limit which the client can accept. In general, if the client does not have any special requirement, we would recommend ANSI/ASQ Z1.4 2003 (R2018) random sampling standard, Single Sampling Plan, AQL 0 Critical 2.5 Major 4.0 Minor, Level I for During Production Check, Level II for Final Random Inspection.

ANSI/ASQ Z1.4 2003 (R2018) (or the equivalent standards ISO 2859, BS 6001, DIN 40.080, NFX 06-021/022)

↑ Use first sampling plan above arrow, if sample size equals or exceeds lot or batch size, do 100 percent inspection

↓ Use first sampling plan below arrow Ac: Acceptance number Re: Rejection number

SGS Inspection Team has equipped with Global network and capability, supporting to arrange inspection at required location from our nearest branch.

5-7 working days in general

On the next working day after the inspection

You can contact SGS at any stage of the production process to apply for inspection when you need, we will provide customized product inspection according to your needs.

"*" indicates required fields

We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.